Recyclable clothes hangers made from hops and waste paper

![[Translate to English:]](/fileadmin/user_upload/Bildschirmfoto_2023-11-13_um_20.37.15.png)

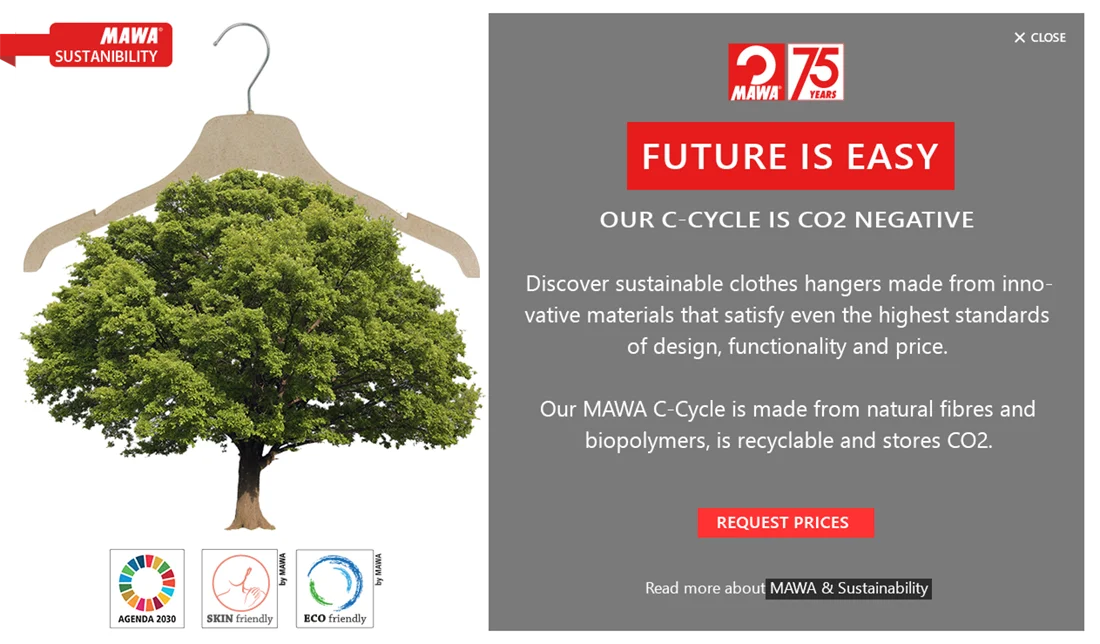

MAWA launches project with TU Dresden to produce hangers based on natural fibres

Most people are familiar with clothes hangers as everyday objects made of metal, wood and plastic. However, the growing awareness of sustainability is leading to an increased demand for bio-based and recyclable products in both the private and commercial sectors. This is also the starting point for the "CellFormDesign" project, which the clothes hanger manufacturer MAWA GmbH launched in September 2023 with the Institute for Natural Materials Technology at the Technical University of Dresden under the direction of Prof. Dr.-Ing. The aim of the project is to develop material-specific technologies for the production of recyclable clothes hangers based on natural fibres. The work is being carried out with financial support from the Federal Ministry of Food and Agriculture.

Vacuum press drying is being further developed

As part of the "CellFormDesign" project, material designs - formulations, structures, modelling, properties - as well as efficient processing and production processes are being developed and evaluated, and hangers are being produced and tested in relevant application environments. CellForm refers to the cellulose-based material group that is being investigated and moulded into hangers. "A bio-based fibre moulding compound is produced from agricultural plant residues and waste, for example hops, as well as waste paper and cellulose, without the addition of fossil polymers," reports Michaela Schenk, owner and Managing Director of MAWA GmbH, adding: "The natural fibres are ground, processed further and pressed and dried into components - at the end of the process, our new P-Cycle eco hanger series will be produced." No cost-intensive hot pressing systems need to be used here; the vacuum press drying patented by TU Dresden serves as a compression and drying process and is being further developed during the project. By comparing the material and energy expenditure in the production, utilisation and post-utilisation phases, it is also possible to compare the environmental impact of newly developed products with conventional products.

Hangers can be recycled in the paper bin

Using experimental material samples and product prototypes with a wide range of variants, the applicability, usability and marketability of the hangers are then subjected to experienced tests and evaluations and customer-focused improvement potential is optimised in an iterative development process. "At the end of the project - in August 2025 - the innovative Eco-Hanger P-Cycle should be available, which is recyclable thanks to its mono-material design. In the private sector, these hangers can be recycled in the paper bin. In the commercial sector, for example in the fashion or hotel industry, it is also possible to take them back and then recycle them, as larger product quantities are utilised in one place, known as closed-loop recycling. The high variability for shape changes with low mould costs also opens up scope in product design."